Introduction

The car industry has been working hard in recent years to lessen its negative environmental effects and promote sustainability. The creation of environmentally friendly automotive interiors is one area of emphasis. Engineering plastic additives have become a potential means of achieving this objective.

1.The Need for Environmentally Friendly

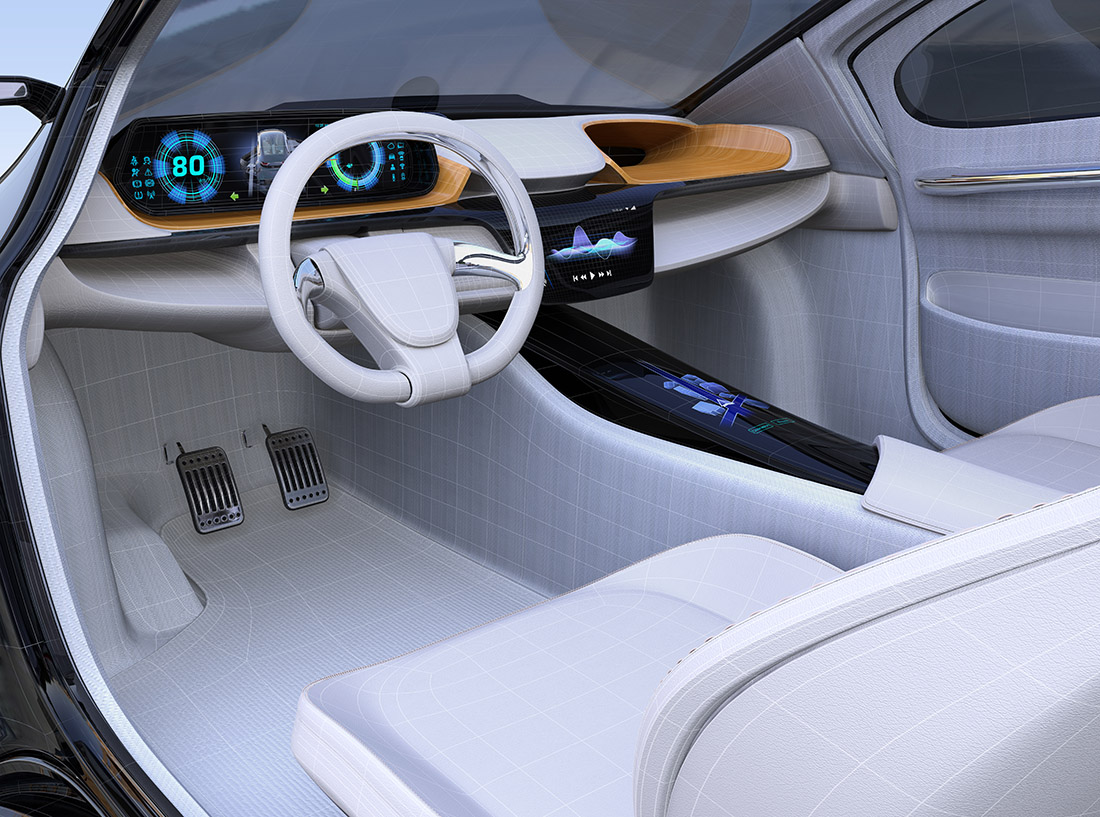

Automotive Interiors The pressure on the automotive industry to minimize its carbon footprint and implement sustainable practices is growing. The environmental impact of a vehicle’s interior is largely influenced by the dashboard, door panels, and seats. PVC and other petroleum-based polymers are examples of traditional materials utilized in these components that are not biodegradable and have a significant carbon footprint. Alternative materials that are more sustainable are therefore required.

2. Introduction to Engineering Plastic Additives

Engineering plastic additives are compounds that are used with plastic to improve its performance and qualities. The strength, resilience, flame resistance, and UV stability of plastics can all be enhanced by these additions. Additionally, they can increase the heat, chemical, and impact resistance of plastics. Engineering plastic additives can help producers make more environmentally friendly and long-lasting automobile interior parts.

3. Advantages of Adding Engineering Plastic to Automotive Interiors

Reduced Impact on the Environment: The lessened environmental effect is one of the main advantages of using engineering plastic additives in automobile interiors. These additives can make it possible to employ bio- or recycled-based polymers, which have a lower carbon footprint than conventional plastics made from petroleum. The car sector may help reduce greenhouse gas emissions and help preserve natural resources by employing sustainable materials.

Engineering plastic additives can improve the tensile strength and lifetime of interior automobile components. These additives can increase the materials’ resistance to fading, wear, and tear, which can increase their lifespan. In turn, this lessens the need for frequent replacements and cuts back on waste production. The overall quality and value of the vehicle can also be improved by the use of durable materials.

Engineering plastic additives can also increase the safety and comfort of car interiors . For instance, flame retardant chemicals can make materials less flammable, making them safer in the event of a fire. UV stability-enhancing additives can stop fading and discoloration brought on by sun exposure, preserving the interior’s visual appeal for a longer period of time. Furthermore, impact resistance-improving compounds can increase the safety of passengers in a crash.

4. Challenges and Limitations

Although engineering plastic additives have many advantages, there are also difficulties and restrictions that must be taken into consideration. The expense of adding these chemicals to automobile interior components is one difficulty. The cost of using environmentally friendly materials and additives may be more than using conventional ones, which will affect the vehicle’s overall price. Furthermore, there can be technological restrictions on using sustainable materials to achieve the needed qualities and performance.

5. Future Prospects and Verdict

The usage of engineering plastic additives in car interiors has considerable potential for advancing the automobile industry’s sustainability objectives. The price and technical restrictions connected with these additions are anticipated to go down as technology develops and more study is done. The need for eco-friendly automobile interiors will rise as a result of manufacturers and customers realizing the value of sustainable practices. The car sector may significantly advance toward a more sustainable future by utilizing the advantages of designing plastic additives.

In conclusion, engineering plastic additives may hold the key to developing environmentally friendly car interiors. The automotive industry may lessen its environmental effect, increase durability and safety, and raise the general caliber of vehicles by adding these compounds into interior components. The future for sustainable automobile interiors is bright, however there are obstacles and constraints to get over. Engineering plastic additives will be essential to accomplishing these objectives as the sector prioritizes sustainability.

Related Products